|

|

Operation Procedure

|

|

Products include kitchen appliances, radio control cars, hi-fi speakers,CD and MP3 player moulds.

|

| |

|

Paddle Moulds

|

|

Specifications:1) Mold base: S1050C steel2) Steel for core and cavity: P203) Plastic material: ABS4) Cavity no: 3 x 15) Parts weight: 83gOuter packing: Wood box

|

| |

|

Plastic Injection Mould

|

|

Specifications:1) Mould base: S1050C steel2) Steel for core and cavity: 718H3) Plastic material: ABS4) Cavity no.: 1 x 15) Parts weight: 400gOuter packing: Wooden box

|

|

|

|

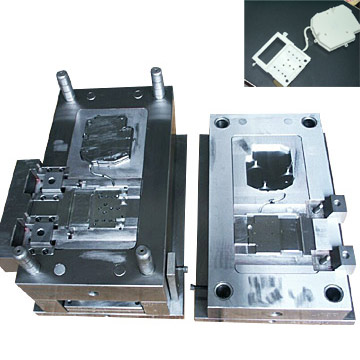

Plastic Injection Mould

|

|

Specifications:1) Mold base: S1050C steel2) Steel for core and cavity: 718H 3) Plastic material: ABS4) Cavity no. : 2 x 15) Parts weight: 56.5g6) Delivery time: Jun 30, 2006Outer packing: Wooden box

|

| |

|

Plastic Injection Mould

|

|

Specifications:1) Mould base: S1050C steel2) Steel for core and cavity: 718H + nitride3) Plastic material: PA4) Cavity no.: 1 x 45) Parts weight: 12g6) Delivery time: Jun 26, 2006Outer packing: Wooden

|

| |

|

Plastic Injection Mould

|

|

Specifications:1) Mold base: S1050C steel2) Steel for core and cavity: 718H + Nitride3) Plastic material: POM4) Cavity no. : 2 x 25) Parts weight: 11.5g6) Delivery time: Jun 27, 2006Outer packing: Woo

|

|

|

|

Plastic Injection Mould

|

|

Features:1) We have more than 40 engineers in our design department2) We make moulds for both in house production and export3) Our engineers help clients analyze and modify product structure withreaso

|

| |

|

Plastic Injection Mould

|

|

Features:1) We have more than 40 engineers in our design department2) We make moulds for both in house production and export3) Our engineers help clients analyze and modify product structure with reas

|

| |

|

Plastic Injection Mould

|

|

1.We have more than 40 engineers in our design department.2. We make moulds for both in house production and export.3.Our engineers help clients analyze and modify productstructure with reason.4.Send

|

|