|

|

Centrifugal Roll-Flow Filow Finisher

|

|

The grinding tank of roll-flow is composed of the bottom rotating plate and the fixed grinding tank. By use of the centrifugal force produced from the high speed rotation of the bottom rotating plate

|

| |

|

CLEANING MACHINE

|

|

SPECIALITY: 1. It is good for remove oil for lathe, punch, fasteners and other handware processing. 2. The finished parts will out automatic when finished the remove oil. It`s no need manpower for op

|

| |

|

Dry Dehydrating Machine

|

|

STRUCTURE: 1. Its support is made by cast pig iron cast, center of garity is stabile and the tube of inner and outer is made by stainless, it is strong and durable. 2. The heater is assembled on the

|

|

|

|

Dry Dehydrating Machine

|

|

STRUCTURE: 1. Its support is made by cast pig iron cast, center of garity is stabile and the tube of inner and outer is made by stainless, it is strong and durable. 2. The heater is assembled on the

|

| |

|

Dry Dehydrating Machine

|

|

STRUCTURE: 1. Its support is made by cast pig iron cast, center of garity is stabile and the tube of inner and outer is made by stainless, it is strong and durable. 2. The heater is assembled on the

|

| |

|

Dry Dehydrating Machine

|

|

STRUCTURE: 1. Its support is made by cast pig iron cast, center of garity is stabile and the tube of inner and outer is made by stainless, it is strong and durable. 2. The heater is assembled on the

|

|

|

|

Dry Dehydrating Machine

|

|

STRUCTURE: 1. Its support is made by cast pig iron cast, center of garity is stabile and the tube of inner and outer is made by stainless, it is strong and durable. 2. The heater is assembled on the

|

| |

|

Dry Dehydrating Machine

|

|

STRUCTURE: 1. Its support is made by cast pig iron cast, center of garity is stabile and the tube of inner and outer is made by stainless, it is strong and durable. 2. The heater is assembled on the

|

| |

|

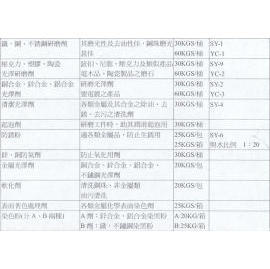

GRINDING LUSTER AGENT

|

|

We provide following different items: 1. Luster agent for iron, stainless steel. 2. Luster agent for plastic, earthenware 3. Luster agent for CU., AL., ZN. 4. Rise in bubbles compound for finish meta

|

|