|

|

Computerized High Precision Cross Cutting Machine

|

|

Main configuration:1) Main control system adopts the most advanced MIC motion integrate controller,5.7 inch touchable human machine interface, YASKAWA AC servo motor.2) High speed photoelectric sensor

|

| |

|

Computerized High Precision Cross Cutting Machine

|

|

1) Main control: adopts the most advanced MIC motion integrate controller, 5.7inchtouchable human machine interface, AC servo motor which made by YASKAWA.2) High speed photoelectric sensor.3) All regu

|

| |

|

Computerized High Precision Cross Cutting Machine

|

|

Main Configuration:1) Main control: Adopts MITSUBISHI PLC programmable logic controller, touch screen and Panasonic AC servo2) All speed regulators adopt vector inverter3) Auto following arm swinging

|

|

|

|

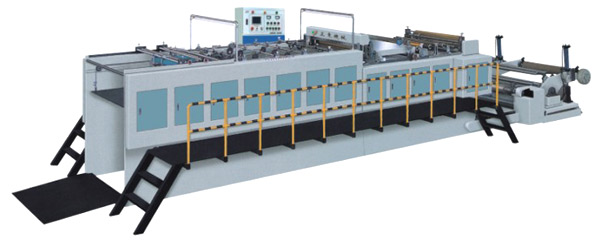

Computerized High Precision Cross Cutting Machine

|

|

Main Technical Parameters:1) Max. width of cutting: 1300mm2) Max. dia. of unwinding: 1600mm3) Cutting width: 200-1300mm4) Cutting speed: 50-70m/min5) Cutting accuracy: 0.15-0.09mm6) Range of paper: 90

|

| |

| |

|

High Precision Cross Cutting Machine

|

|

Main Technical Parameters:1) Max. width of cutting: 1000mm2) Max. dia. of unwinding: Φ1600mm3) Max. length of cutting: 999mm4) Cutting accuracy: ±0.3mm5) Max. thickness of cutting: plastics

|

|

|

|

High Precision Cutting Machine

|

|

Main configuration:1) Main control system adopts the most advanced MIC motion integrate controller,5.7 inch touchable human machine interface, YASKAWA AC servo motor.2) High speed photoelectric sensor

|

| |

|

Three Layer Structure Cross Cutting Machine

|

|

Main Configuration:1) PLC as main control, 3.2 inch touch screen Panasonic AC servo motor for deadlength2) Vector inverter as speed regulator3) Three unique arm swinging for feeding, three layer uniqu

|

| |

|

Bag Making Machine

|

|

This is an unit of multifunction machine applying to outer packaging industry of napkin and sanitary spoy seal and punching for lifting are added into the machine, which solves the problem that irregu

|

|